Laboratory of Applied Surface Science

“The surface often determines the material’s overall functionality.”

Head of Laboratory:

Dr Črtomir Donik

Tel.: +386 1 7401 956, 041 506554

At the Institute of Metals and Technology (IMT), the Laboratory of Applied Surface Science bridges fundamental research in materials science with applied industrial challenges.

Our mission is to understand and control the processes that occur on the surfaces of metallic and inorganic materials, as the surface often determines the material's overall functionality.

With a combination of state-of-the-art equipment and experienced researchers, we provide cutting-edge nanoscale analyses that support both scientific excellence and industrial innovation.

The Laboratory of Applied Surface Science combines world-class instrumentation with deep materials-science expertise to solve the toughest surface and interface challenges. Whether you are exploring advanced metallic coatings, ultra-thin films or nanoscale corrosion phenomena, we deliver high-resolution insights and partner with industry to convert them into performance gains.

Why collaborate with us?

-

State-of-the-art transmission and scanning electron microscopy with FIB capabilities, XPS and in-situ surface analysis up to 1200 °C

-

Established fundamental research (peer‑reviewed publications, academic collaborations) and in delivering industrial solutions (surface durability, coatings, failure analysis).

-

Multi-disciplinary team working at the interface of materials science, surface chemistry and manufacturing

Get in touch with us and let’s explore opportunities for collaboration.

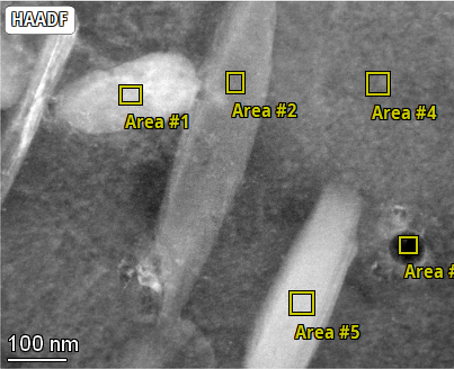

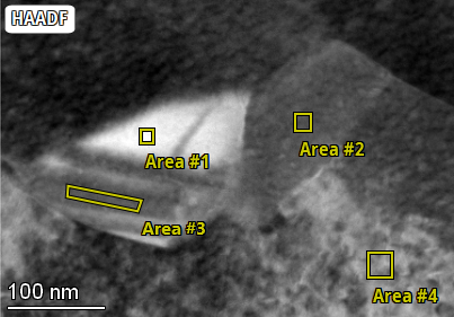

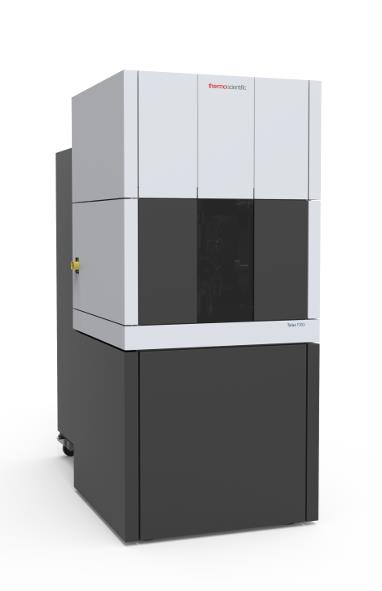

S/TEM — TFS TALOS F200i with Super-X EDS Detector

In the laboratory, we study surfaces and interfacial phenomena that are crucial for the development of advanced materials of the future.

Our primary research areas include:

-

Characterisation of solid surfaces, interfaces, and phases

-

Microstructural and nanostructural studies of metallic and inorganic materials

-

Investigation of physicochemical phenomena: adsorption, segregation, oxidation, corrosion, recrystallisation, catalysis

-

Analysis of thin and ultra-thin films as well as protective coatings

-

Research on gas–solid surface interactions

-

Studies of surfaces after tribological and corrosion tests

-

In situ measurements and observations at temperatures up to 1200 °C with the Protochips stage.

Advanced data and collaboration

-

Integration of data into project databases

-

Support for open-access data, FAIR compliance, and cross-validation with other partners

Our Equipment

We operate one of the most advanced suites of microscopes and analytical methods in Slovenia. This enables us to perform highly precise research comparable to leading European research centres.

Key equipment:

-

ThermoFisher Scientific Talos 200i Transmission Electron Microscope (TEM)

– Analysis of nanostructures and crystal defects

– Super-X EDS detector on all four sides for complete elemental analysis

– ProtoChips system for in situ observation of transformations during heating up to 1200 °C -

ZEISS Crossbeam 550 (FIB-SEM) – (Metallography Laboratory)

– Combines SEM and ion beam milling for 3D reconstructions and TEM sample preparation

– Equipped with EDS and EBSD for compositional and crystallographic analysis -

ThermoFisher Scientific Apreo 2S LoVac (SEM) – (Metallography Laboratory)

– High-performance SEM capable of operating under low-vacuum conditions

– Equipped with EDS and EBSD for full microstructural analysis -

Additional methods

– X-ray Photoelectron Spectroscopy (XPS) (joint facility with the National Institute of Chemistry, Ljubljana)

Sample Preparation Equipment

PECS II 685 (Gatan)

-

Uses argon ion polishing to carefully “clean” the material surface by removing scratches and mechanical damage caused by cutting or grinding.

-

Produces exceptionally smooth and clean surfaces, enabling more reliable SEM, EDS, and EBSD imaging – free of artefacts and mechanical preparation effects.

PIPS II 695 (Gatan Precision Ion Polishing System) (National Institute of Chemistry — located at IMT)

-

Enables the preparation of ultra-thin TEM samples by precise ion polishing.

-

Allows researchers to “see through” the material almost down to the atomic level and study its internal structure without distortions from thicker samples.

JEOL Cross Section Polisher SM-09010

-

Produces high-quality cross-sections of materials, including multilayer coatings, films, and joints. Particularly useful for the study of thin layers, protective coatings, paper, and composites.

-

Since it uses an ion beam instead of mechanical cutting, the sample remains undamaged and free from deformation, allowing more accurate layer analysis.

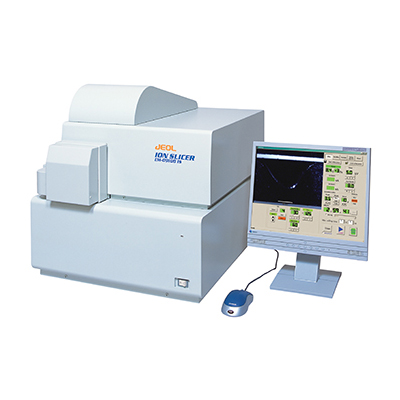

JEOL Ion Slicer 09100IS

-

Advanced tool for preparing large-area, uniformly thin TEM specimens.

-

Especially suitable for sensitive or difficult-to-machine materials, where conventional methods are insufficient. Provides high-quality lamellae for observing materials in their “natural” state at the micro- and nanoscale.

International Collaborations

We actively collaborate with leading academic and research institutions worldwide, including:

-

SUS-Mat, Max-Planck-Institute, Düsseldorf, Germany

-

NIST – National Institute of Standards and Technology, Gaithersburg, MD, USA

-

University of Chemistry and Technology, Prague, Czech Republic

-

Warsaw University of Technology, Warsaw, Poland

-

Faculty of Mechanical Engineering and Naval Architecture, University of Zagreb, Croatia

-

School of Dental Medicine, University of Zagreb, Croatia

-

Politecnico di Milano, Milano, Italy

Inštitut

Inštitut