Laboratory of Metallography

“Where Metals Tell their Story“

Head of Laboratory: Dr. Irena Paulin

Phone: +386 1 4701 964, +386 1 4701 965

E-mail: irena.paulin@imt.si (direct) · info@imt.si (general)

Address: Lepi pot 11, SI-1000 Ljubljana,

Slovenia

Overview

The Laboratory of Metallography performs advanced microstructural and surface characterisation of metallic and composite materials. Our expertise supports European research and innovation projects—including Horizon Europe, M-ERA-Net, Pathfinder, ARIS and bilateral R&D collaborations—as well as national industrial research initiatives.

We combine accredited laboratory competence with academic research excellence, linking microstructure analysis to materials design, performance, and reliability in novel alloys, coatings, additive-manufactured materials, and composites. In 2007 Laboratory of Metallography gained accreditation from Slovenian Accreditation. Annex to the acreditation certificate.

Research focus and project role

The laboratory contributes to research and development in several thematic areas relevant to European frameworks:

-

Advanced metallic materials: steels, light alloys, intermetallics, and high-entropy alloys

-

Additive manufacturing and joining technologies: correlation of processing parameters with microstructure and mechanical response

-

Materials for energy and transport: microstructural stability, oxidation, corrosion, and fatigue

-

Surface and interface engineering: coatings, diffusion layers, and tribological systems

-

Failure and degradation mechanisms: multiscale analysis of fracture and deformation phenomena

-

Digital metallography and AI-assisted image analysis: quantitative evaluation and data integration across materials platforms

In EU projects, the Laboratory of Metallography acts as a research and testing partner, providing:

-

Accredited metallographic and microanalytical methods

-

Expert interpretation and reporting aligned with research objectives

-

Support for dissemination and data management (FAIR principles)

-

Contribution to materials databases and standardisation activities.

Research capabilities

Microstructural characterisation

-

Optical and field-emission scanning electron microscopy (FE-SEM)

-

EBSD phase and orientation mapping (in cooperation with LPA)

-

EDS/WDS elemental microanalysis

-

Quantitative image analysis of grains, inclusions, pores, and precipitates (in cooperation with LPA)

Thermal and mechanical behaviour

-

Dilatometry for solid-state phase transformations

-

Microhardness and correlation with mechanical properties (in cooperation with LMP)

Fractography and surface analysis

-

Identification and interpretation of fracture mechanisms (in cooperation with LMP)

-

Examination of coatings, diffusion layers, and surfaces under wear or corrosion (in cooperation with LPA)

Advanced data and collaboration

-

Integration of microstructural data into project databases

-

Support for open-access data, FAIR compliance, and cross-validation with other partners

Equipment

- SEM Thermo Fisher Scientific Apreo 2S with EDS/EBSD

Advanced field-emission SEM for high-resolution imaging and crystallographic analysis. -

ZEISS Crossbeam 550 FIB-SEM Gemini II

Dual-beam FIB-SEM system for site-specific sectioning, 3D reconstruction, and EBSD mapping; fitted with EDAX Octane Elite EDS and Hikari Super EBSD camera. -

Axio Imager Z2m – Metallographic Optical Microscope

The LM is a high-performance optical microscope for advanced metallographic analysis, offering bright/dark-field, DIC, and polarised imaging. It integrates with Zeiss ZEN software for automated documentation, large-area stitching, and SEM/EBSD data correlation. -

Optical Microscope Nikon Microphot FXA

Equipped with an Olympus DP73 digital camera and image-analysis software for quantitative metallography. -

Confocal Optical Microscope Alicona InfiniteFocus

3D optical surface profiler for roughness and topography measurements. -

Digital Stereo Microscope KEYENCE VHX-X1F Series

High-resolution 3D stereo microscope for detailed imaging of surfaces and microstructures.

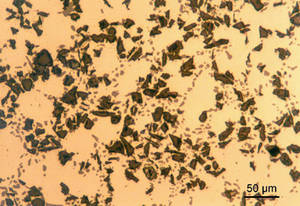

Al-SiC composite, as polished

Al-SiC composite, as polished

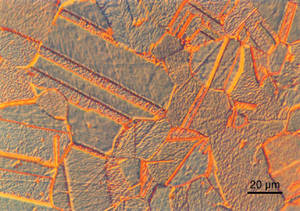

Grey iron with lamellar graphite, etched in Nital, polarised light

Grey iron with lamellar graphite, etched in Nital, polarised light

Copper, etched, Nomarski interference contrast

Copper, etched, Nomarski interference contrast

Austenite stainless steel, colour etched

Austenite stainless steel, colour etched

Why collaborate with us

-

Proven participation in European and national research consortia

-

Accredited analytical methods ensure data credibility

-

Advanced instrumentation for comprehensive materials characterisation

-

Experienced researchers in metallography, surface science, and data interpretation

-

Open, collaborative approach aligned with IMT’s mission to bridge research and industry

Within the Laboratory of Metallography, also operate:

Advanced Additive Manufacturing and Powder Technology Laboratory (A2MPT)

- Aconity3D MINI

Laboratory-scale metal AM system (SLM) with substrate heating up to 800 °C.

- Aconity3D MIDI+ LPBF System

Dual-laser (400 W and 1000/3000 W) laser powder bed fusion (LPBF) printer with substrate pre-heating to 1200 °C.

- Hybrid Plasma/Induction Ultrasonic Atomiser AMAZEMET 2.0

For production of fine metallic powders for AM and rapid-solidification research.

Inštitut

Inštitut