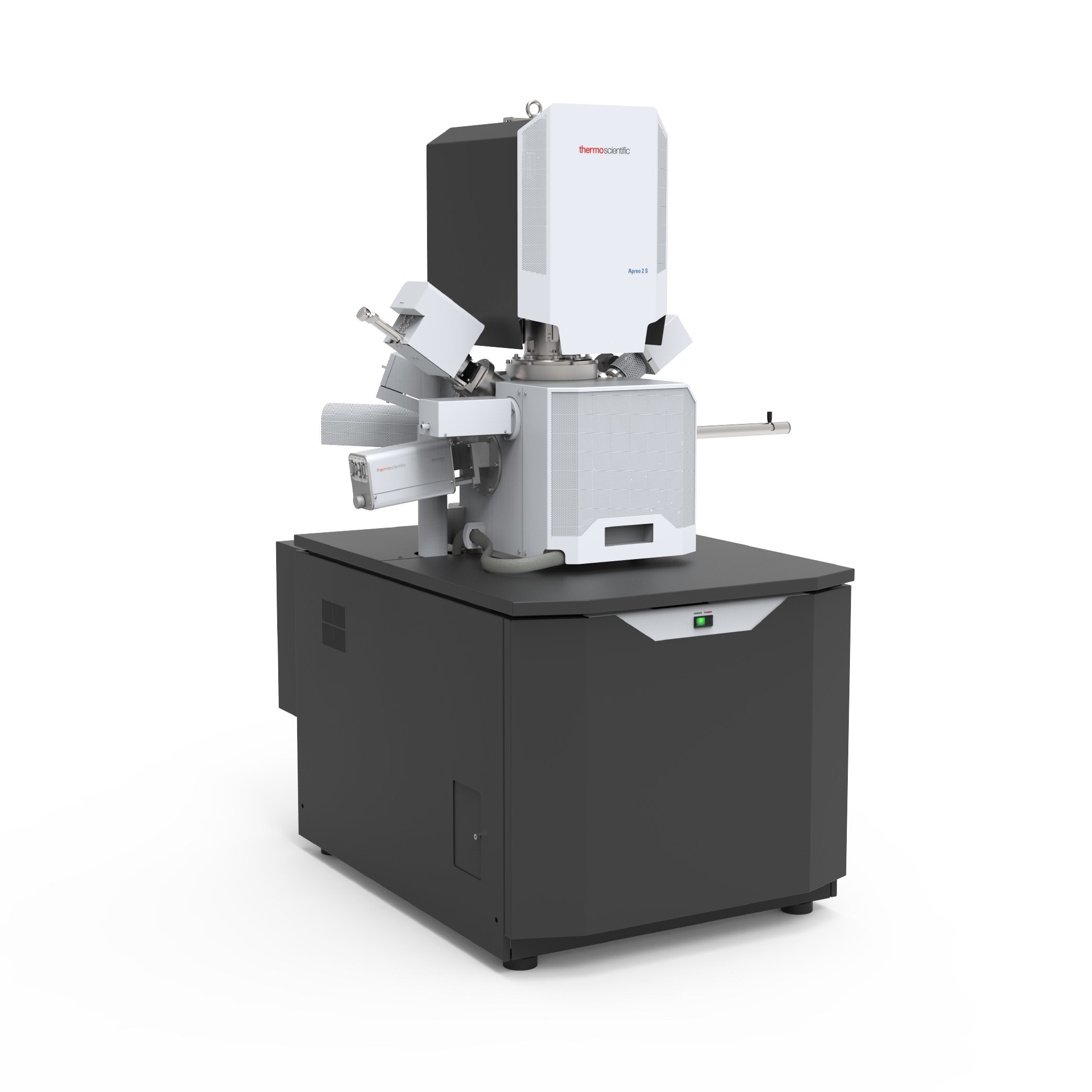

SEM

ThermoFisher Apreo 2S LoVac SEM

At the Institute of Metals and Technology (IMT), we use the ThermoFisher Apreo 2S LoVac SEM, which combines high-resolution imaging, advanced chemical and structural analysis, and a system designed for non-conductive materials. This instrument is a key part of our surface analysis facilities, enabling comprehensive material characterisation – from visualisation to quantitative analysis – with exceptional versatility.

Technical Features and Capabilities

-

Field Emission Gun (FEG) electron source: provides a stable, finely focused electron beam, delivering high resolution even at low accelerating voltages.

-

Oxford EDS 65 mm² detector: enables fast and sensitive energy-dispersive X-ray spectroscopy (EDS), ideal for elemental mapping, detecting trace elements, and supporting high-throughput analytical tasks.

-

EBSD camera Symmetry S3: a high-performance EBSD system that allows rapid collection of crystallographic orientation data, phase identification, and texture analysis. Together with Aztec and Aztec Crystal software, it enables indexing, orientation mapping, and advanced statistical evaluations.

-

Low-Vacuum (LoVac) system: allows operation at elevated chamber pressures (up to several hundred Pa), minimizing charging effects in non-conductive or partially conductive samples and often eliminating the need for conductive coatings.

-

Carbon GIS (Gas Injection System): integrated system for localized carbon deposition on the sample, improving surface conductivity and reducing charging effects, which results in higher-quality SEM imaging of insulating materials.

Why the Apreo 2S LoVac is important for IMT

-

Enhanced analysis of non-conductive materials: The LoVac and Carbon GIS systems make it possible to study ceramics, composites, and insulators without coating, preserving the sample’s natural surface and minimizing artifacts.

-

Combined EDS + EBSD + SEM imaging: Delivers simultaneous information on morphology, topography, crystallographic structure, and chemical composition. This is crucial in materials research, where microstructure and phase changes directly influence functionality.

-

High resolution and flexibility: The FEG source, low-voltage imaging capabilities, and advanced software enable detailed characterization of even highly sensitive samples under demanding conditions.

-

Productivity and broader collaboration: The instrument supports fast, automated analyses with an advanced user interface and integrated workflows. This ensures efficiency and facilitates participation in European research projects and industrial R&D collaborations.

Inštitut

Inštitut